| CAD/CAM |

|

CAD stands for Computer

Aided Design.

CAD systems consist of the hardware and software needed to enable

designers to produce accurate plans and drawings.

|

|

|

|

A CAD workstation may be a standalone

or a networked computer. It would have

...

- a powerful processor - needed

for some of the processes such as 3D rendering.

- a powerful graphics card and a

high resolution monitor.

- input devices such as mouse, light

pen, graphics tablet, keyboard.

- output devices such as printer, graph

plotter.

- backing store devices such as a hard drive

for saving designs.

|

|

|

|

|

CAD software would allow a user to...

- draw lines, and polygons

of any size.

- draw curves, circles.

- draw on a number of different layers.

- zoom for adding fine detail.

- perform transformations such as scaling

or rotating.

- rendering of surfaces.

- view objects in 2D or 3D

using different lighting effects, walkthroughs.

Some CAD software allows analysis

of stresses, liquid flow etc...or testing of electronic circuits. |

|

|

|

|

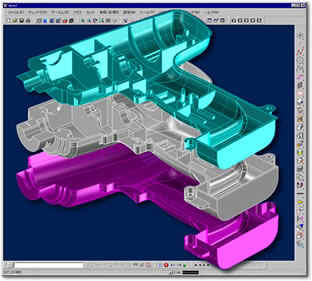

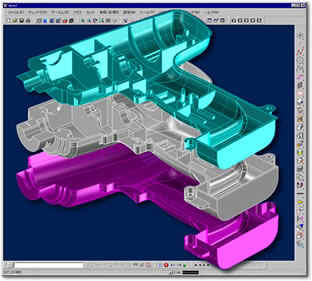

Examples of CAD :

-

Designing Components and moulds.

-

Design of kitchen or garden.

-

Design of electronic circuit boards.

-

fashion design.

|

|

|

CAM stands for Computer

Aided Manufacture.

In a CAD/CAM system, output from a CAD design is converted into a

sequence of instructions for special machines which then manufacture the

component.

CNC (Computer Numerical Control)

machines use numerical input as instructions for the machine to

manufacture an object.

CNC machines may be..

- a lathe for turning metal or wood.

- milling machines for cutting metal shapes.

- drills

- welding machines

- soldering machines

- water jet machines

- lasers

- router or engraver

- robotic arms

Some CNC machines have automatic tool-changing facilities.

|

|

|

Advantages of CAD/CAM systems:

- good accuracy and precision.

- fine detail can be added.

- reliable and consistent results.

- fast development of designs.

- design facilities such as 3D views and walkthroughs and lighting

changes can not easily be done on paper.

- easy editing of designs.

- some automatic calculations such as material costings.

|

|

|

Disadvantages of CAD/CAM systems:

- Expensive to buy and set up the hardware and software.

- Staff will need to be trained to use it.

|

|

|

|

|

|

|

|

|

|

|

| |

| |