GENERAL COURSE INFORMATION

Here you will find documents and information regarding the course overall.

-

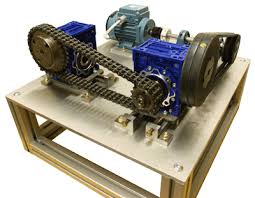

QET3/029 Maintenance of Mechanical Systems

This section contains useful information for the unit and covers six learning outcomes:

LO 1 Understand the maintenance function

LO 2 Understand lubricants and lubrication systems

LO 3 Understand bearing operations, types, materials and causes of failure

LO 4 Understand power transmissions, principles of operation and failure patterns

LO 5 Understand seals and sealing principles

LO 6 Understand and use dismantling and re-assembly techniquesPlease click on a book to read

-

Important: - Please Read!

Please follow the link to the Ten Basic Rules of Netiquette or Internet Etiquette. Please read this as it is very important to follow the basic rules whilst commenting on a forum.

-

UPLOAD your project summary/ initial ideas here. It is important that you get some ideas down as soon as possible, fill in the summary sheet and upload it here before 22nd November. This is so we can address any problems together.

-

Project summary proforma. Download this file and answer the short questions. This will help you get your project started.

-

Staff and Contact Details

Unit 029 will be delivered by Ian Griffiths

Email is ian.griffiths@nptcgroup.ac.uk

Teams Phone Number is 0330 818 8345

Ian Griffiths will be contactable during 9am to 4:30pm Mon to Friday